Development of control systems for loaders

Development of control systems for loaders

Transport and logisticDevelopment of control systems for loaders Transport and logistic

Intelligent control systems make forklift operation safer, more efficient and more accurate. Their functioning is ensured by a reliable software and hardware, which is controlled in a comfortable interface. Thus, the work of the staff is greatly simplified, and the risk of making mistakes is reduced to almost a minimum. The capabilities of the system, which are implemented during its development, may differ depending on the type of loader and the format of its use within a particular company. The most common functionality includes:

- Weighing the cargo. Scale integration allows the loader to accurately determine the weight of each pallet, bucket or bale. The software can then add up the set number of lifts to determine, for example, the total weight of one large load, or calculate the total number of weighings, which will allow you to track the amount of work done by the loader at the end of the working day.

- Automatic angle control. This feature allows the operator to set the desired position of the beams and fix it in the system memory. Once the loader is set at the desired angle, the function is disabled and allows you to continue with the setup.

- Setting operating range limits. It is not uncommon for a forklift to work inside a low space, such as in containers or small warehouses, which can limit its maximum height. To eliminate the occurrence of emergencies, the operator can set the desired range of beams so that they do not rise above the specified value.

- Shake function. The adjustable shake function will help the operator select the most suitable range for the job. For example, it can be useful for removing soil residue from a bucket, spreading sand on roads, and other purposes.

- End position damping. The function prevents the front loader from reaching the maximum high or low position. That is, the loader will learn to “understand” when the hydraulic cylinder reaches the limit range and will automatically stop its movement shortly before the final value. In particular, this will significantly reduce the wear rate of the machine.

What technologies are used to develop forklift control systems

TechnologiesWhat technologies are used to develop forklift control systems Technologies

In the process of developing automated control systems for loaders, a different technological stack can be involved. Often, it all depends on the features of the software, its tasks and the platform on which it is planned to work:

- Mobile applications. This category includes software that is installed not only on smartphones, but also on any device running on IOS and Android operating systems. For example, it may be a control tablet installed in the cab of a loader. The development of such solutions for IOS is carried out in the Objective-C and Swift programming languages, for Android – in Java and Kotlin. In addition, there are cross-platform technologies, such as Flutter / Dart, with which you can create applications that operate on both operating systems.

- Desktop applications. They are installed on the user’s personal computer or laptop and are characterized by high performance. Their development often involves the programming languages Python or PHP, as well as their frameworks — Django/Flask or Yii2/Laravel, respectively.

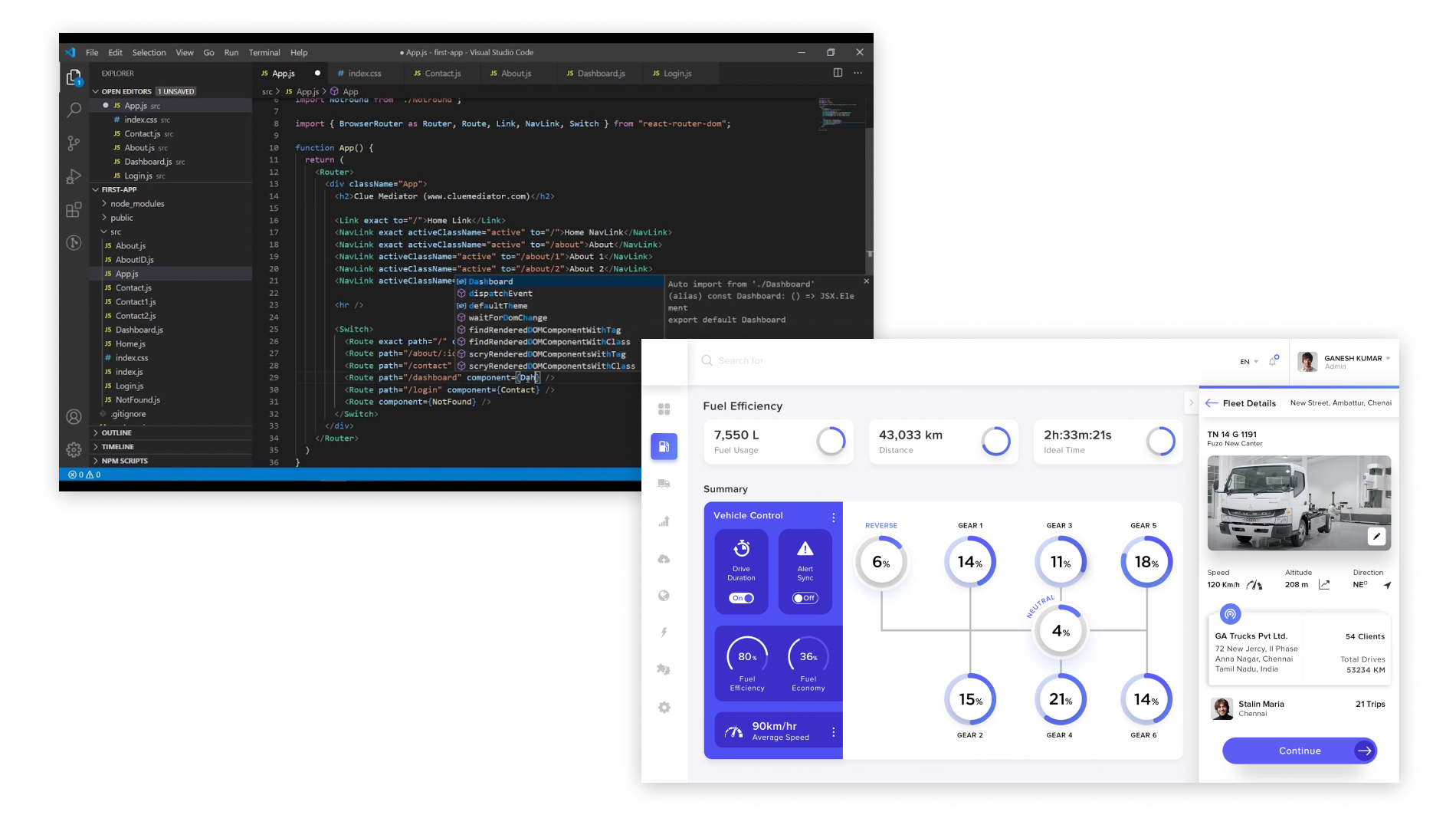

- Web applications. They work in the browser interface and do not depend on the operating system. For example, they can be run on PC, IOS and Android devices, and their correct display on screens of different sizes is guaranteed by an adaptive interface. The front-end part of such solutions can be implemented using static technologies such as HTML, CSS and JavaScript, or reactive technologies such as Vue.js and React.js. The server part is built in PHP programming languages and its Yii2/Laravel frameworks, in Python and Django/Flask frameworks, or in JavaScript. The latter refers to the Node.js platform.

The technology stack affects many software parameters. For example, it depends on how easily the software can scale, how long it takes to develop, how quickly it will process user requests, and so on. To find the perfect balance, this choice is often made by the development team during the system design phase.

Forklift control system development process

Development stagesForklift control system development process Development stages

The implementation of intelligent control systems for loaders is carried out step by step. This approach allows you to create high-quality and reliable software that exactly meets the requirements of the client. As a rule, there are six main stages of development, and let’s look at what kind of work is performed on each of them.

Stage 1. Idea and information gathering

The creation of any software begins with an idea – in this case, it is to create an automated system that will increase the efficiency of forklifts in the enterprise. After that, the collection of information begins, within which specialists need to determine:

- how the software will work;

- client’s requirements;

- what resources will be required for its implementation;

- is it possible to develop the system from a technical point of view.

To answer these questions, personal or online meetings with the customer are held, and the existing IT infrastructure of the company is analyzed.

Stage 2. Technical documentation and design

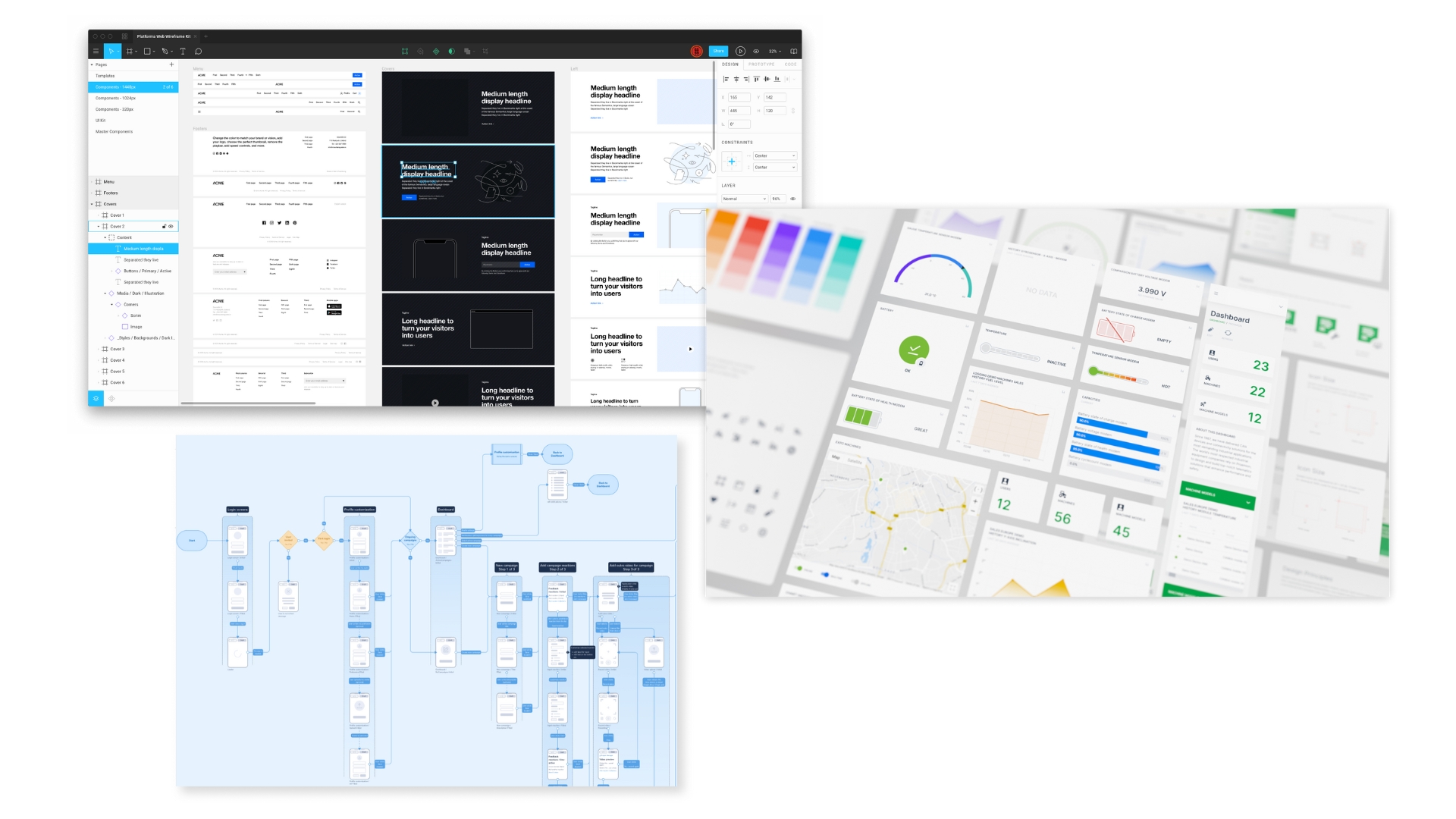

The technical documentation and description of the specifications provide a clear framework within which the developers will operate in the subsequent stages. This is necessary to obtain a predictable result in terms of technical capabilities and external design, since not one specialist, but a whole team will work on the project. The result of this stage will be a full-fledged product prototype, including:

- a stack of technologies that will be used in production;

- a detailed description of the functionality and tasks that it will solve;

- mockups of unique user interface pages with a navigation system;

- implementation plan;

- external services that will be integrated into the application.

When the prototype is ready, it is presented to the client and, if necessary, adjustments are made to it. With this approach, the cost of changes will be minimal, since any, even global changes in the prototype are carried out in a matter of hours.

Stage 3. UI design development

The task of a UI designer is to create a pleasant and intuitive interface that end users will interact with. It makes the perception of complex things simple and clear, which will reduce the time that operators need to train.

The implementation of the design is often carried out individually, taking into account the needs of a particular project. Of course, template solutions can also be used to create it, but in this case, you will have to compromise on convenience and functionality, which is not always acceptable in such complex projects.

Stage 4. Programming

Loader control system programming is a fairly general concept, which consists of two stages:

- Frontend development. This includes developing a user interface based on previously approved design layouts. The frontend acts as a link between the user and the server, and its main task is to receive client requests and transfer them to the server, and after processing, display the result. However, if the frontend is developed using reactive technologies, its capabilities are significantly expanded – in this case, it will be able to independently process some of the requests without sending them to the server, which positively affects the performance and responsiveness of the software.

- Backend development. If the frontend is only responsible for transmitting client requests, then the backend is responsible for everything that happens next: mathematical calculations, functions, database management, and so on. At the same time, the backend is located on the server and is not available to the end user. At the development stage of this part, programmers form the architecture of the code, build the logic of the functionality and integrate all external services, for example, elements of the company’s existing IT infrastructure.

Stage 5. Testing

After the implementation of the technical part, the project moves to the testing stage, where

QA-engineers check the correctness of the functionality and the readiness of the product for production.

Depending on the chosen development model, QA engineers can be involved in the project at different stages, starting with the design.

This helps to identify software problems at an early stage, which significantly reduces the cost of fixing them.

Stage 6. Technical support and development

After the product is put into production and started working in real conditions, operators may encounter unexpected errors that were not detected during the testing phase. In this case, the developers study the bugs and quickly fix them as part of the technical support of the product.

You also need to understand that in the course of planning it is impossible to take into account all the nuances, because of which, over time, it may be necessary to create additional functionality or improve the existing one. To solve such problems, specialists release patches with updates or a new version of the product, which are developed additionally, taking into account new requirements.

Development of loader control systems in AVADA MEDIA

Development of loader control systems in AVADA MEDIA

By using automated control systems for forklifts, you can significantly increase the productivity of their work, as well as increase safety on the territory of the enterprise. The development of such solutions is one of the main activities of AVADA MEDIA.

In our work, we use only modern and efficient technologies that make it possible to translate into reality innovative functionality of any complexity. Also, for the implementation of such tasks, we have already formed teams of specialists with well-established communication and experience in working together.

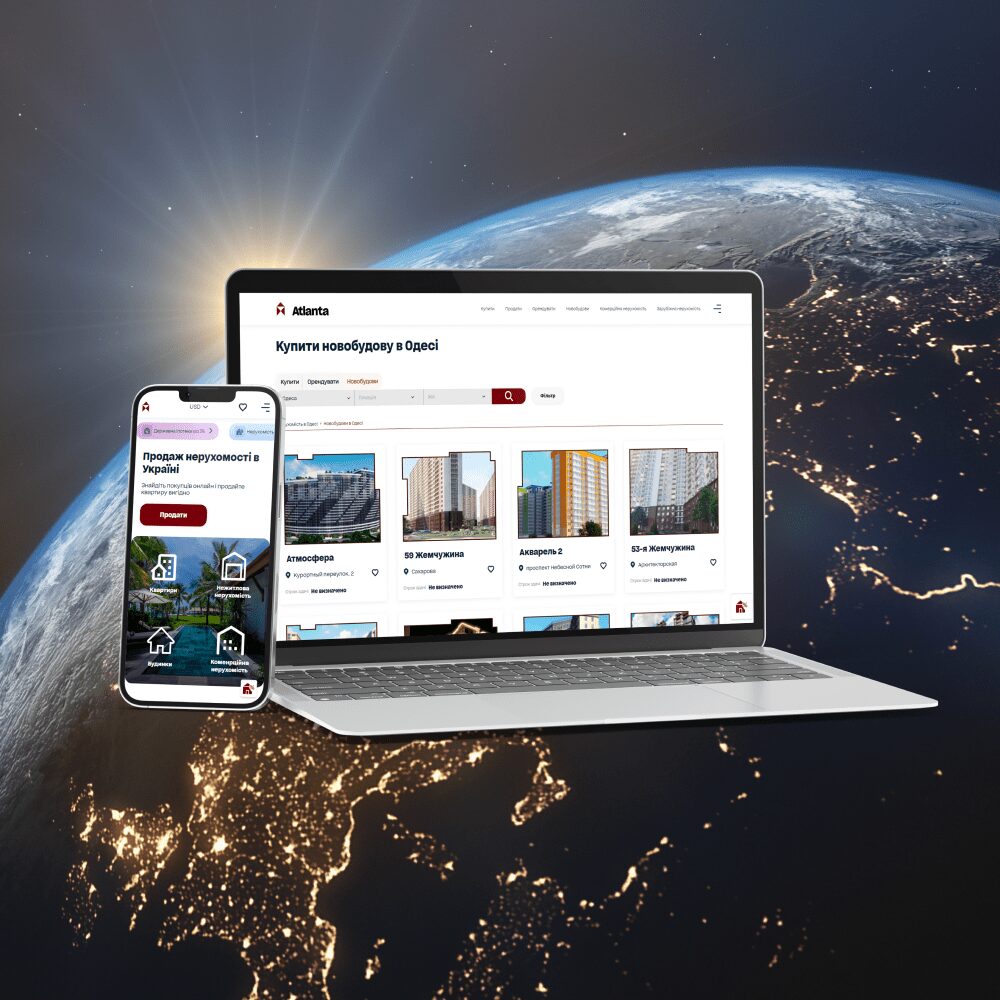

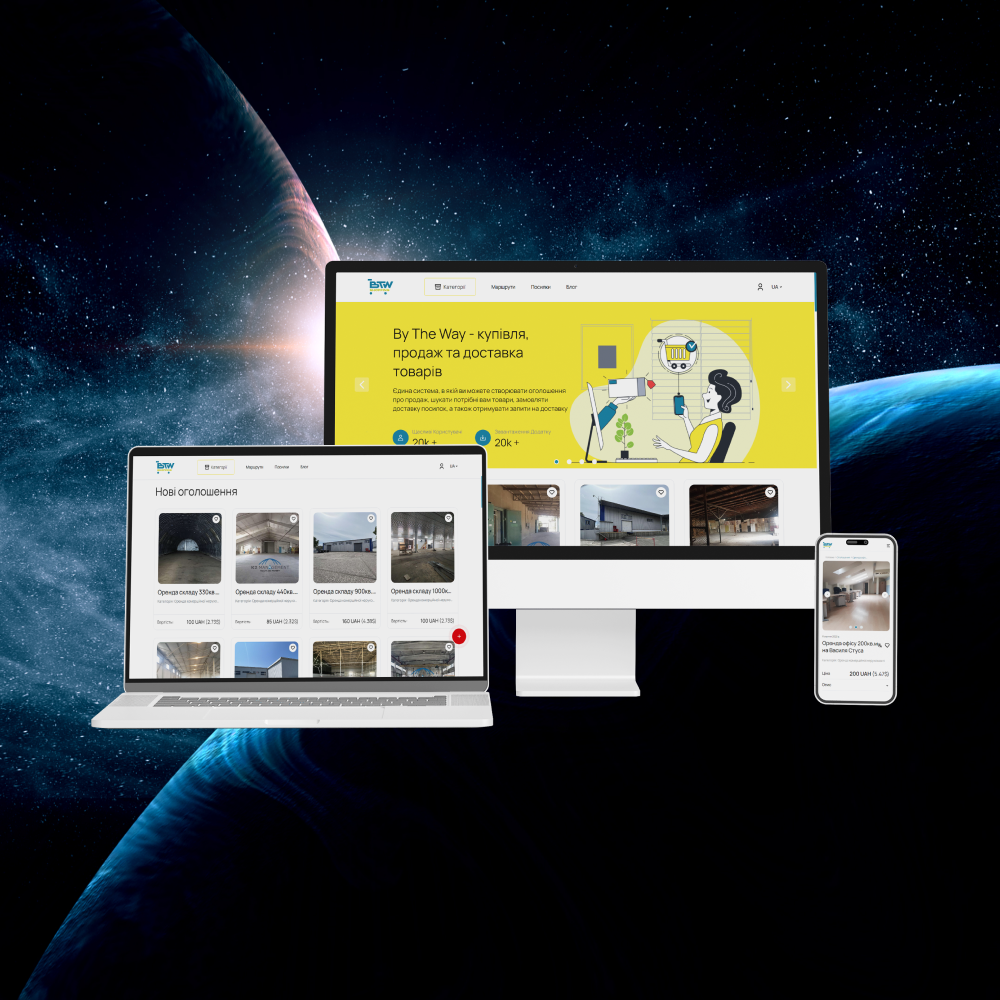

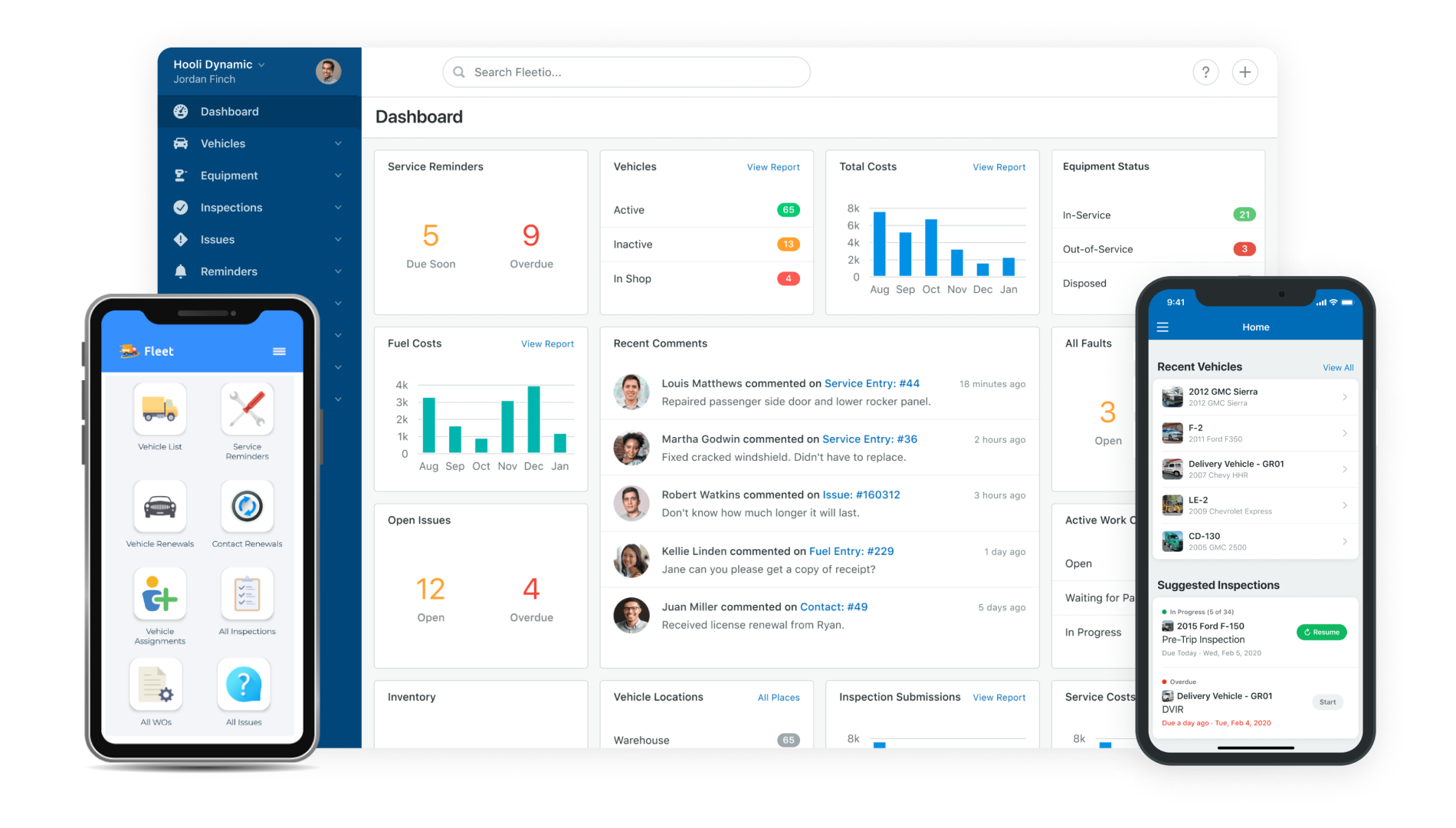

Fresh works

We create space projectsFresh works

The best confirmation of our qualifications and professionalism are the stories of the success of our clients and the differences in their business before and after working with us.

Our clients

What they say about usOur clients What they say about us

Successful projects are created only by the team

Our teamSuccessful projects

are created only by the team Our team

Contact the experts

Have a question?Contact the experts Have a question?

-

Phone:+ 38 (097) 036 29 32

-

E-mail:info@avada-media.com.ua