Every manufacturing enterprise is a complex mechanism where inconsistencies in planning, supply disruptions, raw material overruns, unfinished orders, and the human factor can slow down even the most promising project. In the age of digitalization, manual management of production processes makes an enterprise inefficient and uncompetitive. That is why a CRM system for production is not just a convenient tool, but a necessity for effective growth and scaling.

With AVADA MEDIA, you will get a reliable partner for the growth and development of your company. You can order the development of an individual CRM for production from us, which will become a key element in managing the entire production cycle.

CRM for enterprises is a powerful ecosystem for managing orders, logistics and warehouse accounting, quality control, human resources, and even production capacity analytics. It is a comprehensive software solution that allows you to digitize data, reduce costs, automate and make core processes more transparent. Unlike classic ERP systems, CRM for enterprise focuses not only on internal processes but also on relationships with customers, suppliers, and contractors.

Automation is needed by every enterprise that is developing, increasing volumes, and planning to scale. There are also a number of factors that point to the critical need to develop CRM for production management, for example:

Any of these factors hinders the growth of a manufacturing company. Therefore, the development of an individual management system is not an expense, but a long-term investment in the company’s development.

In the face of global competition, companies that operate using outdated management methods risk losing both profits and market positions. Therefore, modern production requires accuracy, efficiency, and speed. Full automation of production helps to eliminate chaos in business processes, minimize errors, and create a transparent and manageable system. Let’s take a closer look at the benefits of using a CRM system for an enterprise.

Optimization of production cycles

After the implementation of CRM, the company can record and analyze each stage of the production cycle – from receiving raw materials to shipping finished products. This allows you to see the real picture of the company’s work, identify bottlenecks in time, and eliminate delays. For example, automation of industrial production helps to

Automation of document flow

Applications, invoices, contracts, specifications, and other documentation are generated automatically in CRM. This helps to eliminate human errors, combine all documents in an electronic archive, simplify processes such as auditing and certification.

Intelligent planning

Comprehensive automation of production processes helps to predict production line utilization, take into account seasonality of demand, adjust supply plans, and ensure that orders are fulfilled on time. This is especially important for companies with a long supply chain.

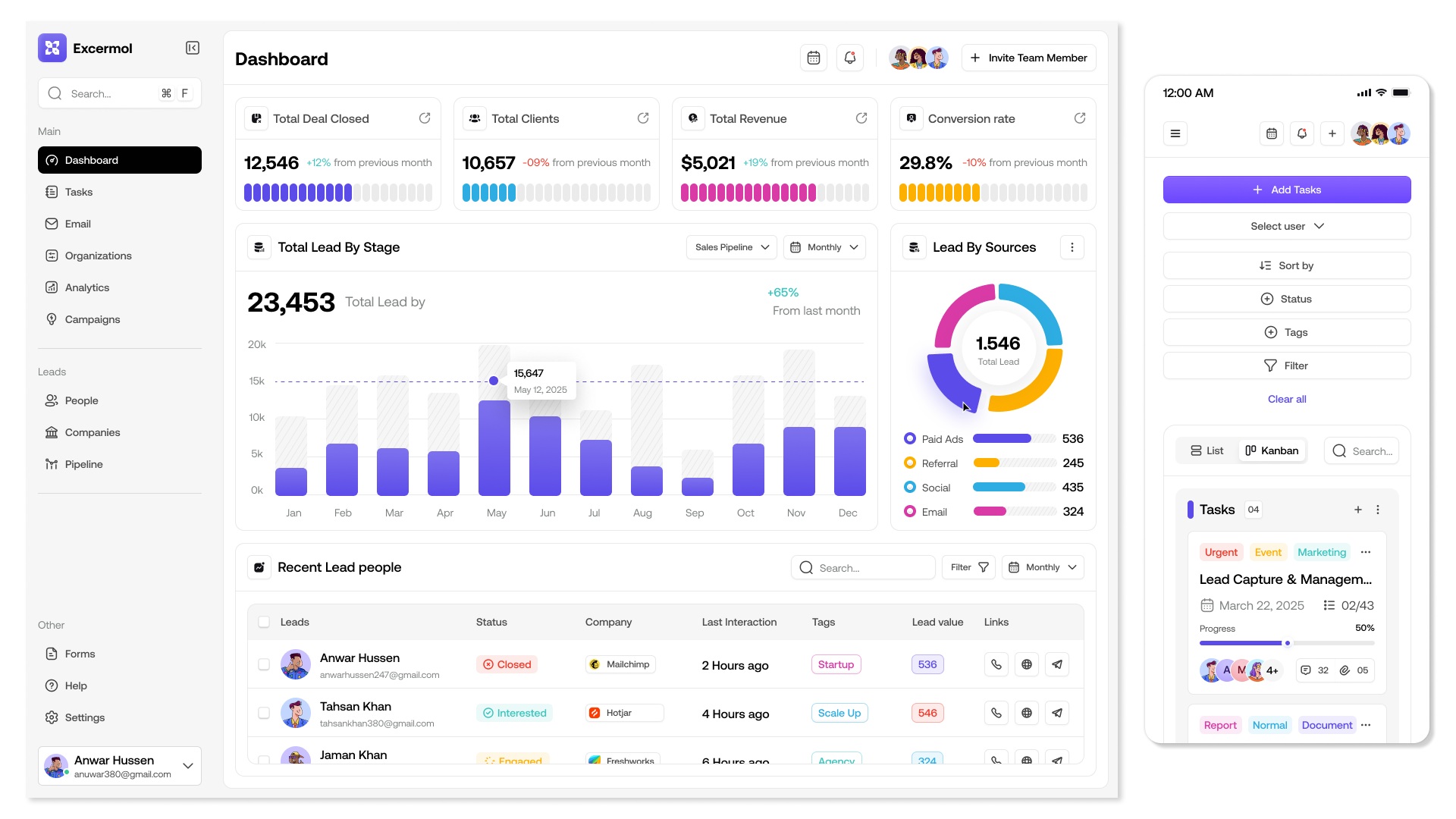

Effective interaction with suppliers, customers, and partners

CRM automates communication with customers, data exchange with suppliers and contractors, tracks order statuses, sends notifications, and allows you to keep a history of interactions to personalize the service. Automation of the company’s production simplifies procurement and supply management, and increases customer satisfaction.

Integration with other systems, equipment, and IoT

Modern production management systems can be connected to sensors on production lines to monitor the status of machines, assess their utilization, and prevent the need for maintenance, reducing the likelihood of unplanned breakdowns. And thanks to the ability to integrate with other systems (ERP, MES, WMS), you can create a single information space.

Optimization of materials and inventory costs

Implementation of CRM at the enterprise allows you to keep accurate records of materials and components, avoiding unnecessary purchases and reducing warehouse stocks. Automation of production and logistics for the delivery of materials reduces transportation costs, and control over the shelf life of materials avoids writing off unspoiled goods.

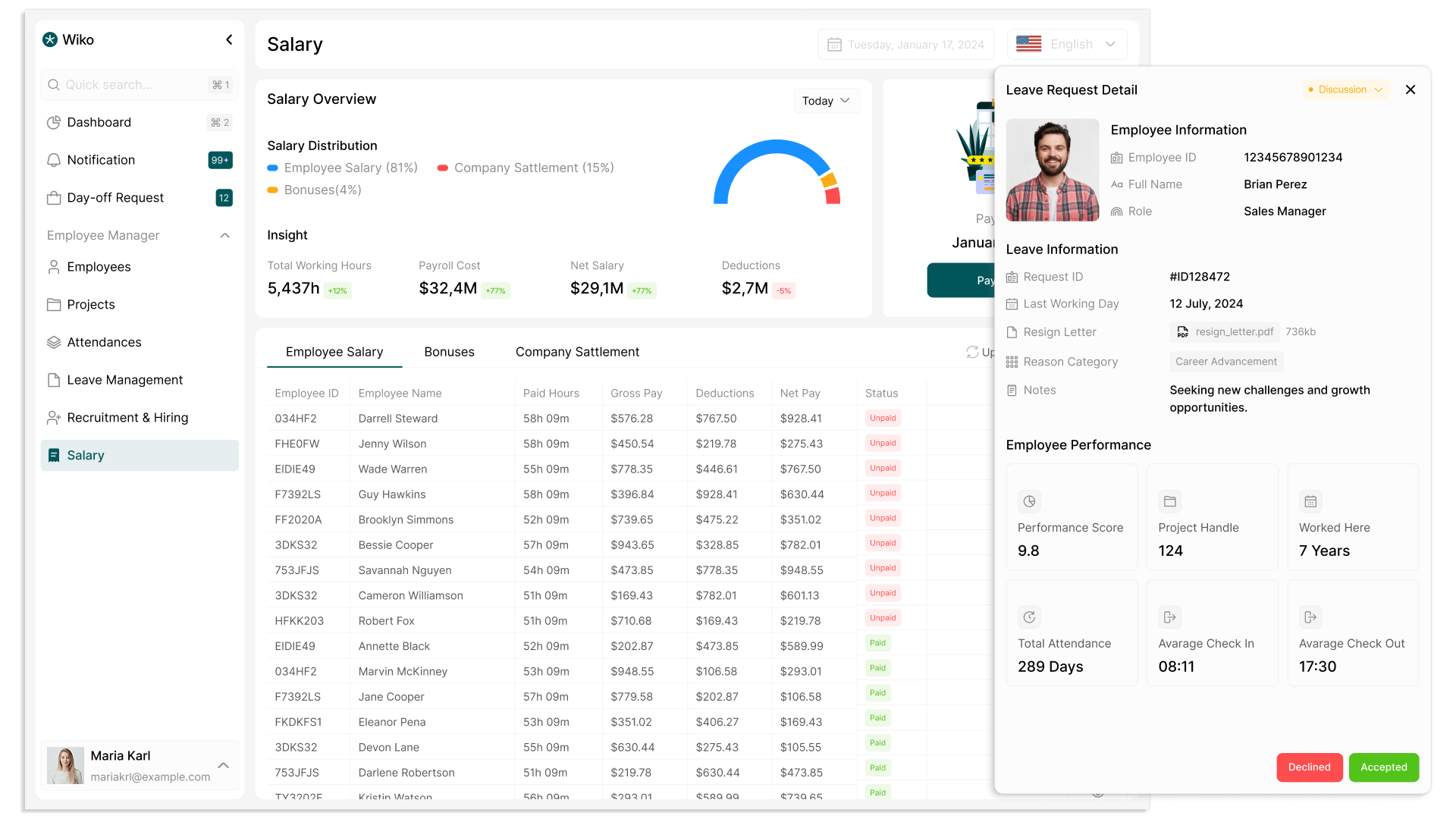

Increase staff efficiency

Automation of manufacturing enterprises frees up employees’ time from routine processes for the most important and creative tasks, facilitates decision-making through access to the necessary information in real time. CRM also allows you to evaluate employee productivity.

Developing CRM for manufacturing has several key goals, each of which is aimed at increasing business efficiency and sustainability.

Automation of production processes is relevant for companies in various industries. Let’s take a look at which ones benefit the most from developing their own management system:

Any manufacturing enterprise that seeks to reduce paperwork and accelerate data exchange needs to order the development of CRM for production.

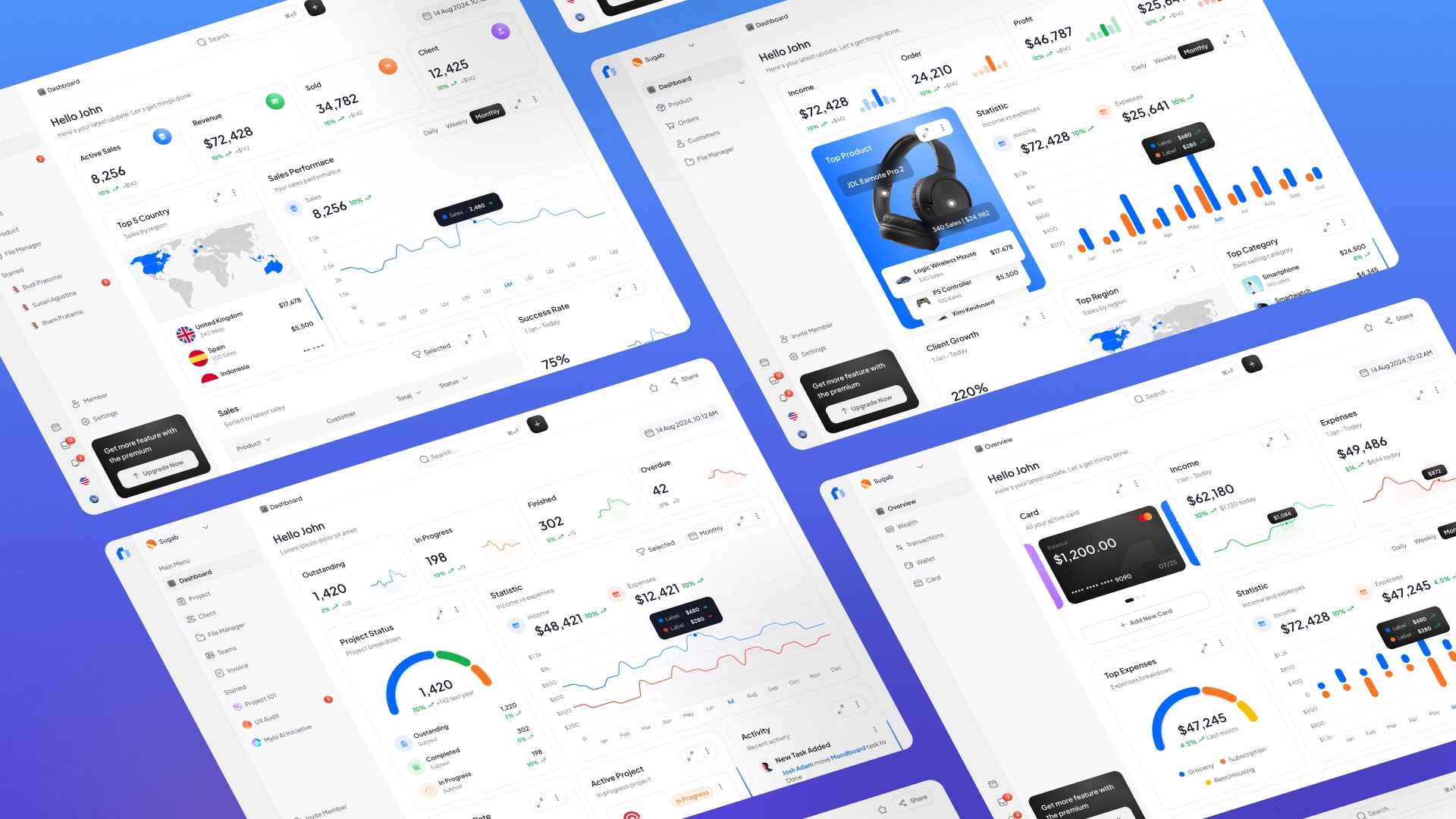

CRM systems for enterprises

Customized CRM for a manufacturing company covers all stages – from order receipt to shipment to the customer. It can have modules to perform the following functions.

Management of production orders:

For example, a furniture factory receives an order for a kitchen set. The system generates an order, assigns it a unique number, attaches drawings, and monitors its progress through the stages: cutting, assembly, and packaging.

Planning and control:

For example, CRM for a printing house generates a plan for the week, distributing tasks between shifts depending on the availability of machines. If one of the lines breaks down, the system automatically rebuilds the schedule and notifies the foreman.

Quality control:

For example, when a packaging defect is detected, CRM for the food industry captures it in a photo, automatically creates an internal complaint, and notifies the technologist.

Warehouse and raw material management:

For example, if a large order for the manufacture of pipes is received at a production facility, CRM for a steel company checks the availability of the required diameters in the warehouse and automatically generates a purchase order for the missing materials.

Personnel management in production:

For example, a foreman sets a sewing plan for a shift. At the end of the shift, the CRM for sewing production calculates the output of each seamstress, taking into account the complexity of the product.

Financial module:

For example, as part of the analysis of the cost of a batch of drugs, CRM for a pharmaceutical company will show an overspend of packages by 10%, help analyze all possible causes and suggest ways to eliminate them.

Logistics and shipment:

For example, when a manufacturer of window structures forms a shipment for a client in another city, CRM for the window business automatically distributes orders for flights, prints invoices and calculates the optimal route.

BI and production analytics:

For example, in a CRM system for foundry production, on a dashboard with defect indicators for a month, management notices an increase in defects in one of the sections and initiates an audit.

The choice of the necessary program modules for production depends on:

Implementing a CRM system for production is a complex and sequential process. Each stage plays an important role in creating a functional and reliable product.

Business and goal analysis

At the first stage, an analysis of the enterprise’s business processes is carried out. Problem areas, bottlenecks, production needs are identified: which processes can be automated, what data needs to be collected and what tasks the system should cover. The analysis also includes market research, competitor research and identification of necessary integrations with other systems.

Technical specifications

Based on the analysis, a technical specification is created – a document that describes the requirements for the future CRM for an industrial enterprise: functions, integration, security and scalability. The technical specifications are the basis for further development and help create a program that fully meets the client’s request.

Design and prototyping

At this stage, a logical structure of the system is created, user scenario diagrams are developed, modules and their interaction are designed. Next, interactive prototypes of interfaces are formed, which allow you to visually assess the convenience of working with the system. Integrated production management systems will operate under high load conditions, so it is important for users to quickly navigate the system.

UX/UI design development

A convenient and intuitive interface is an important element of CRM. Here, designers need to take into account the specifics of work in production: operators, managers, logisticians and other employees should easily find the necessary functions and work without delays. UX/UI designers use modern tools – Figma, Adobe XD, Sketch, which allow them to create adaptive interfaces.

Creating software code

At this stage, programmers bring the project to life. For the client part (frontend), they use React, Angular or Vue.js, providing a convenient and fast interface. The server part is implemented using Python, Node.js or PHP, which allow them to process large amounts of information and effectively interact with databases. They implement integration with the necessary services via API.

Testing

QA engineers conduct multi-stage testing to identify errors, verify the correct operation of all modules and data security. It is important to check the stability of the system under high loads, since production CRMs must process large amounts of data in real time.

Release and user training

After successful testing, the system is transferred to the customer’s server or placed in a cloud storage and implemented in the working environment. At this stage, personnel training is carried out, data transfer from existing systems is carried out, integrations are configured, and reporting is initially configured. Our specialists ensure a phased implementation of the CRM system at the enterprise so as not to slow down current processes.

Project support and development

After implementation, CRM requires support and development. Technical support of the production management system includes analysis of software efficiency, regular updates, functionality improvements, and integration of new technologies – for example, AI and machine learning for demand forecasting and resource optimization.

CRM system development

Ready-made production management programs are universal, but cannot fully meet the specifics of a manufacturing business. Only by ordering individual development can you create a tool that will fully meet the processes, structure and goals of the enterprise.

Why is it worth ordering the development of a management system for an enterprise, and not buying a ready-made program:

Manufacturing companies always operate under unprecedented challenges. If your business is facing difficulties in managing orders, logistics, warehouse or personnel, needs cost optimization, flexibility and efficiency – it’s time to switch to digital rails.

AVADA MEDIA has been providing individual CRM system development services for all areas and scales of business for more than 10 years. We will help you create an intelligent platform that will not only organize production processes, but also bring the enterprise to a new level of efficiency, minimize risks and increase profitability.

How is CRM for manufacturing different from ERP systems?

CRM is focused on managing relationships with customers, suppliers, and contractors, as well as on process automation. ERP is more focused on enterprise resource planning, including accounting, finance, and inventory management.

Can a CRM for manufacturing capture equipment data?

Customized industrial production management systems synchronize with IoT devices, CNC machines, and other monitoring systems. This allows you to receive real-time data on the condition of equipment, predict maintenance, and prevent downtime.

How does CRM help manage product quality?

With CRM, production is easier to control because the program records data on each batch of products, tracks production stages, and stores data on quality checks and customer complaints. This helps to quickly identify and eliminate defects, as well as improve production processes.

Is CRM for manufacturing management suitable for remote departments?

Cloud CRM systems allow you to centrally manage multiple factories or production sites, receive operational reports, and remotely coordinate staff work.

Is CRM suitable for small production?

Individual CRM for a factory scales to any business needs. Small businesses can use basic functions for order and inventory management, and as they grow, implement additional modules.

Can CRM be configured to work with B2B and B2C simultaneously?

Automated production planning and management systems support work with both models. For B2B, this includes managing long-term contracts and partners, and for B2C, order automation, customer interaction, and marketing tools.

What tasks does production automation take on (examples)?

In metallurgy, CRM helps analyze productivity, and in garment production, it helps manage fabric batches and distribute orders between workshops.

How much do automated custom production management systems cost?

The cost of development depends on the scale of the enterprise, the number of integrations with other systems and the specifics of production processes. A simple CRM for basic processes requires less time and resources than complex custom solutions.

How long does it take to develop and implement a CRM system for production?

The development period for an individual production management system starts from four months. Ready-made solutions can be implemented faster, but they will have to be adapted to the company’s business processes, which will require additional costs, downtime and time.

Is integration with production equipment (scales, scanners, machines) possible?

Yes, it is possible to implement integration with equipment via API, OPC servers, or other protocols so that the system can receive and process data from scales, data collection terminals, barcode scanners, PLC controllers, etc.

Our works

Contact the experts Have a question?

Developed by AVADA-MEDIA™

The user, filling out an application on the website https://avada-media.ua/ (hereinafter referred to as the Site), agrees to the terms of this Consent for the processing of personal data (hereinafter referred to as the Consent) in accordance with the Law of Ukraine “On the collection of personal data”. Acceptance of the offer of the Consent is the sending of an application from the Site or an order from the Operator by telephone of the Site.

The user gives his consent to the processing of his personal data with the following conditions:

1. This Consent is given to the processing of personal data both without and using automation tools.

2. Consent applies to the following information: name, phone, email.

3. Consent to the processing of personal data is given in order to provide the User with an answer to the application, further conclude and fulfill obligations under the contracts, provide customer support, inform about services that, in the opinion of the Operator, may be of interest to the User, conduct surveys and market research.

4. The User grants the Operator the right to carry out the following actions (operations) with personal data: collection, recording, systematization, accumulation, storage, clarification (updating, changing), use, depersonalization, blocking, deletion and destruction, transfer to third parties, with the consent of the subject of personal data and compliance with measures to protect personal data from unauthorized access.

5. Personal data is processed by the Operator until all necessary procedures are completed. Also, processing can be stopped at the request of the User by e-mail: info@avada-media.com.ua

6. The User confirms that by giving Consent, he acts freely, by his will and in his interest.

7. This Consent is valid indefinitely until the termination of the processing of personal data for the reasons specified in clause 5 of this document.

Send CV

Contact us in any convenient way for you:

+ 38 (097) 036 29 32