The development of the retail market has led to a significant increase in freight traffic. According to Statista, by 2024 the global cargo transportation market will grow to 92.1 billion tons, which is almost twice as much as in 2015. This growth has created a need for more productive software solutions for supply chain digitization.

Today there are three main requirements for the transportation of goods – security, speed and traceability. Through automation, the trucking industry is able to manage the fleet more efficiently, inform customers instantly and make important decisions on the road.

Depending on the line of business and business model, companies may have different needs from a technological point of view.

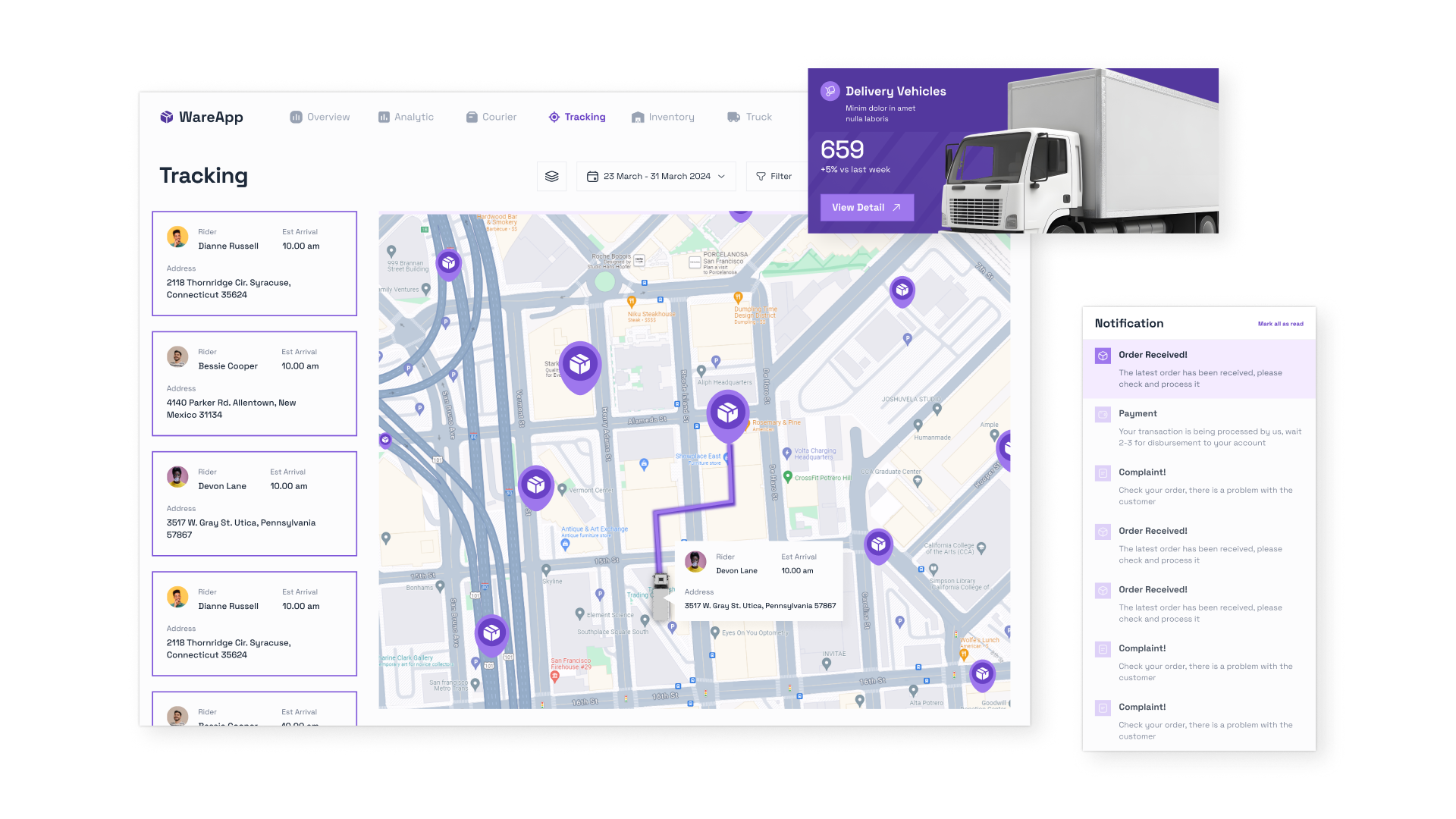

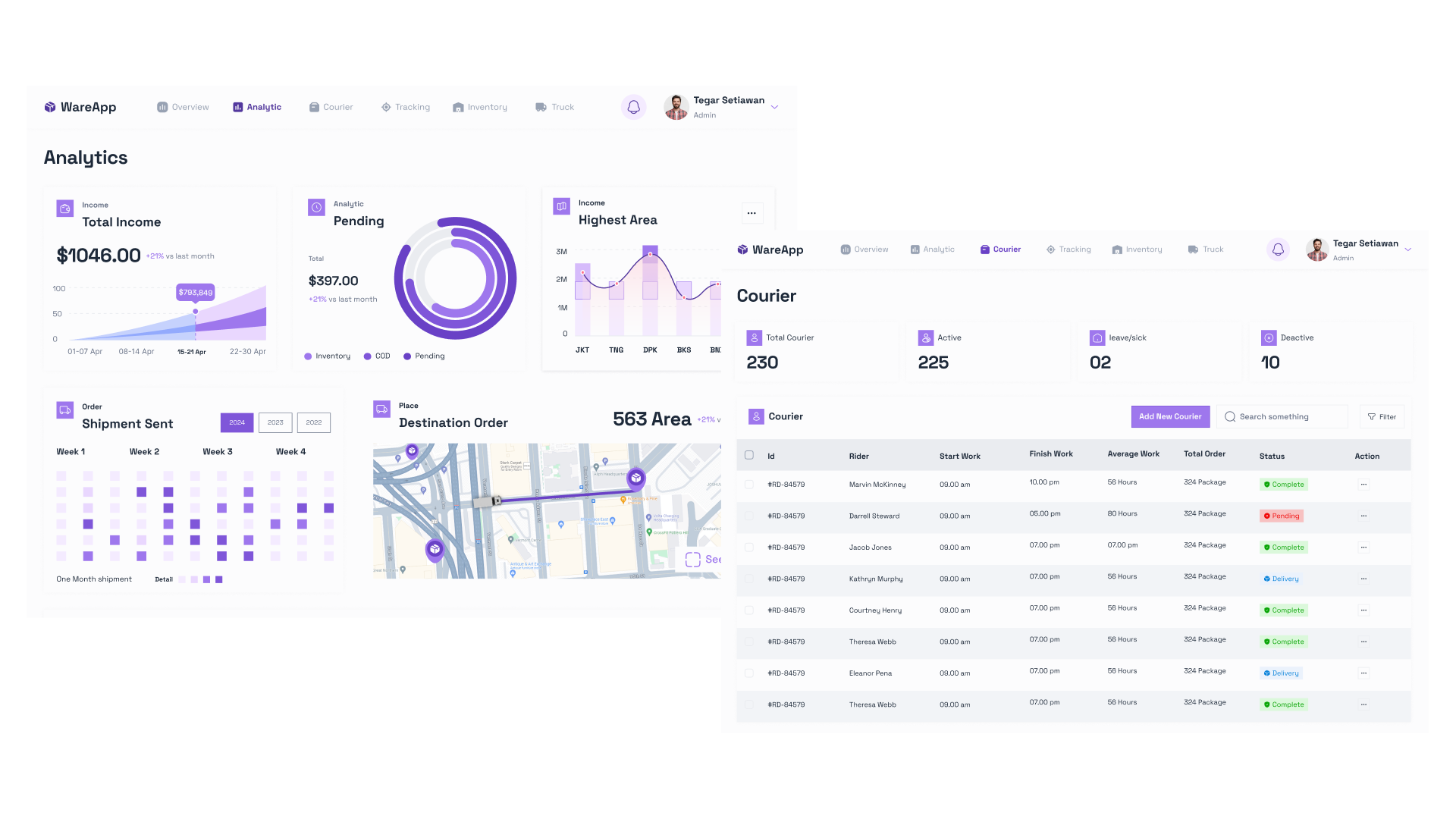

In the transport business, CRM allows you to control the delivery of goods at all stages of the supply chain and automatically assign tasks to responsible employees. Such systems contain all the necessary tools in one interface, and can also be integrated with other programs that the company already uses in its work.

The main tasks that CRM performs in logistics:

When developing our own CRM system for a business, we take into account all the specifics of its work, due to which the effectiveness of the software solution increases significantly compared to universal standard products.

Intelligent systems for managing grain and container terminals are designed to protect the company from various errors in the process of receiving, shipping and transporting grain crops. At the same time, they help to reduce production losses and increase the efficiency of employees.

The main tasks that such systems perform:

Warehouse logistics software is used to record, manage and distribute inventory. It helps to organize an efficient process of cargo delivery to the end user and, often, closely interacts with the company’s transport logistics services.

The main tasks that warehouse logistics software can perform:

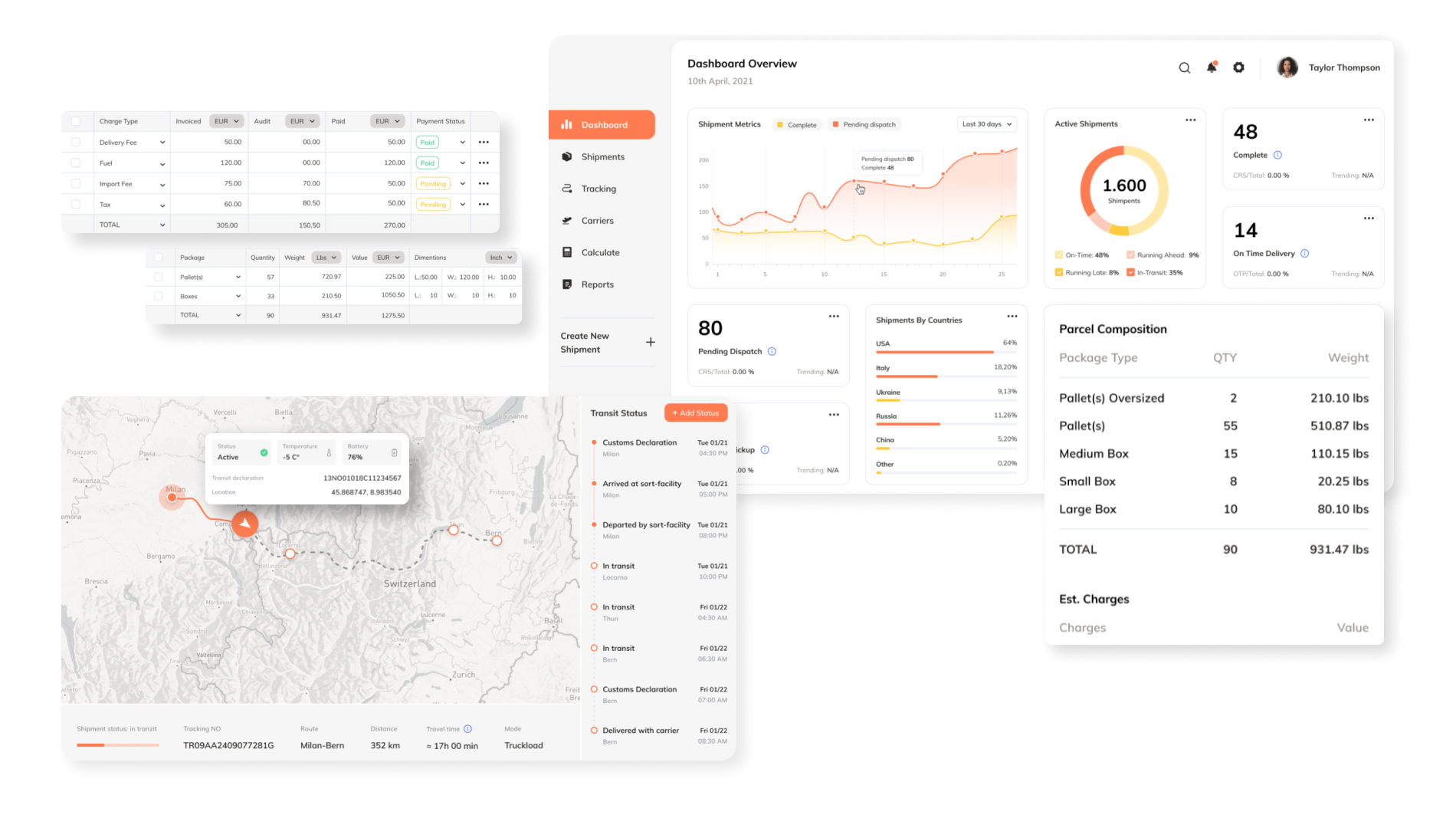

The software for sea container transportation helps to optimize the document flow, taking into account the customs legislation of different countries, and also automates the calculation of the cost of transportation and interaction with customers. This gives businesses the opportunity to reduce the operational burden on employees and focus on their development.

Some important functions that such software can perform are:

In the container shipping industry, large companies often prefer decentralized solutions. Blockchain technology increases the transparency and security of the project, as well as reduces the costs associated with the legal support of transactions through the use of smart contracts.

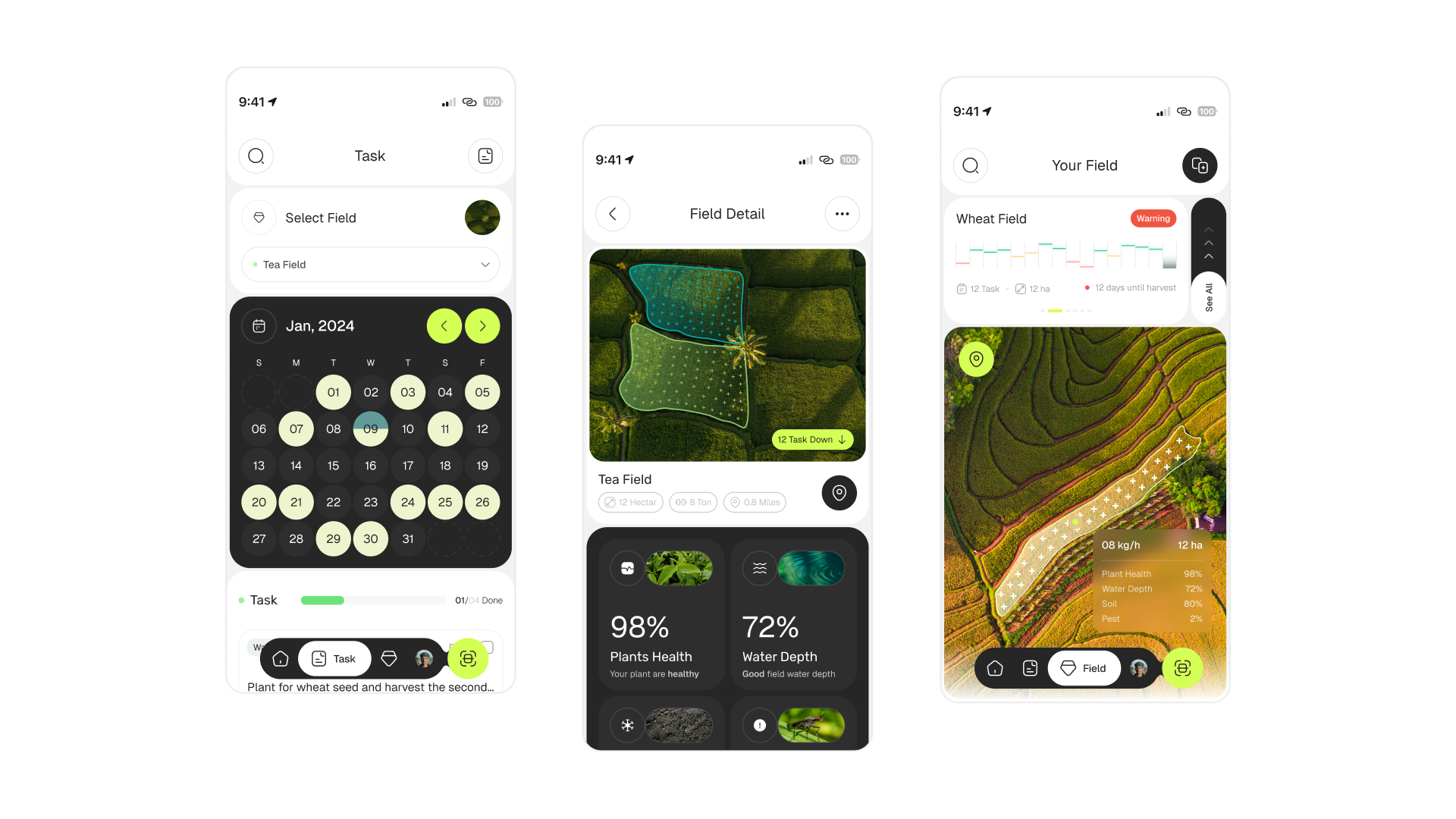

Often, such software is installed on a smartphone and provides the driver with all the useful information regarding route optimization, documentation and vehicle maintenance. For example, an application might include the following features:

Such systems are designed to optimize the company’s logistics. They store information about the fleet and drivers, cargo, customers and scheduled transportation, and perform a number of important functions:

The use of specialized applications makes the company’s logistics as convenient and transparent as possible, and also improves the quality of customer service, since goods will always be delivered on time thanks to quality planning.

Access control and management systems, or ACS for short, are designed to restrict vehicle access to enterprise facilities. They automatically recognize a person or machine that intends to enter the protected area and independently decide on access authorization, based on the programmed data.

Such systems can be used to ensure the security of facilities, control the working hours of employees, maintain a database of personnel and company visitors, as well as for many other purposes.

Such systems are installed across the roadway and automatically record the weight of cars passing through them, and are also able to determine the load on each individual axle. This is necessary in order to prevent excessive load on the coating.

ASVK are able to automatically read the necessary data about cars from hardware devices – scales, video cameras and other things, analyze them and make a decision regarding the authorization of the passage of the vehicle.

Commercial road software enables companies to fully automate the process of paying and passing vehicles, as well as keep accurate statistics to analyze business efficiency.

Such systems can also be equipped with weight and size control, which will allow you to calculate the amount of payment depending on the load that the car puts on the road surface.

(Ua) Системи автоматичної тарифікації в паркувальних комплексах виконують відразу кілька функцій:

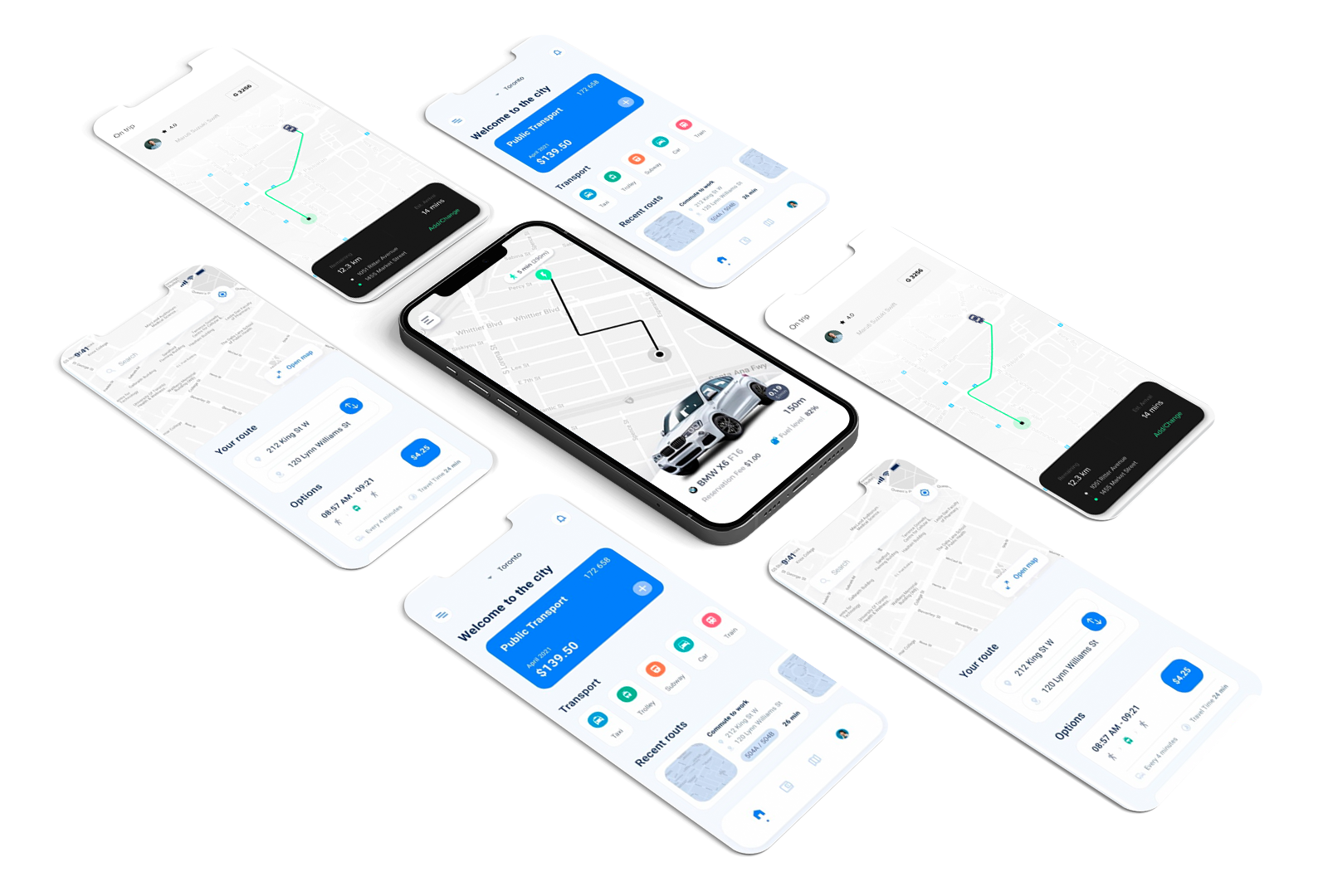

Complexes for dispatch services of taxis and taxi companies are used to automate routine tasks in this area and increase the speed of order processing. They may include many interconnected modules and systems that are developed in accordance with the internal business processes of each individual company, for example:

Also, AVADA MEDIA specialists can develop systems for car rental. They include a separate user application for customers and a built-in GPS tracker with embedded development – programming the software of the car itself.

Thus, the company at any time can track the location of the vehicle, wherever it is.

To develop projects, AVADA MEDIA specialists use a modern technological stack that allows you to create reliable and secure software. The choice of a specific technology often depends on the features of the product and the platform on which it will work:

Before starting software development, AVADA MEDIA specialists conduct a thorough analysis of the business and its current IT infrastructure, develop an interface prototype and detailed terms of reference to achieve a high level of economic efficiency.

When implementing each project, we use already formed teams of developers with experience in working together, which allows us to guarantee consistently high quality and speed of development.

Our works

Contact the experts Have a question?

The user, filling out an application on the website https://avada-media.ua/ (hereinafter referred to as the Site), agrees to the terms of this Consent for the processing of personal data (hereinafter referred to as the Consent) in accordance with the Law of Ukraine “On the collection of personal data”. Acceptance of the offer of the Consent is the sending of an application from the Site or an order from the Operator by telephone of the Site.

The user gives his consent to the processing of his personal data with the following conditions:

1. This Consent is given to the processing of personal data both without and using automation tools.

2. Consent applies to the following information: name, phone, email.

3. Consent to the processing of personal data is given in order to provide the User with an answer to the application, further conclude and fulfill obligations under the contracts, provide customer support, inform about services that, in the opinion of the Operator, may be of interest to the User, conduct surveys and market research.

4. The User grants the Operator the right to carry out the following actions (operations) with personal data: collection, recording, systematization, accumulation, storage, clarification (updating, changing), use, depersonalization, blocking, deletion and destruction, transfer to third parties, with the consent of the subject of personal data and compliance with measures to protect personal data from unauthorized access.

5. Personal data is processed by the Operator until all necessary procedures are completed. Also, processing can be stopped at the request of the User by e-mail: info@avada-media.com.ua

6. The User confirms that by giving Consent, he acts freely, by his will and in his interest.

7. This Consent is valid indefinitely until the termination of the processing of personal data for the reasons specified in clause 5 of this document.

Send CV

Contact us in any convenient way for you:

+ 38 (097) 036 29 32