The work of oil terminals is associated with the performance of many routine tasks: the reception and transshipment of petroleum products, data processing, transport control and documentation. This is really just the tip of the iceberg, and there are often hundreds of other processes going on behind the scenes. To keep track of everything, companies have to make a choice – hire a large staff of professional employees, which is quite expensive, or automate work using specialized management systems.

If we talk about the second option, then it has its advantages – this is improved control and increased security on the territory of the enterprise.

In addition, intelligent systems practically eliminate the risks of making mistakes due to the human factor, which is extremely important when working with petroleum products.

When creating such systems, not only Software is often involved, but also Embedded development – that is, the development of embedded systems for controlling hardware platforms, such as oil elevators, temperature sensors, and others. As a result, operators get the opportunity not only to control the processes that take place inside the terminal, but also to manage them inside the working software interface without leaving the office.

Intelligent oil terminal management systems are always individual solutions that are created based on the needs of a particular business. Therefore, their functionality for each individual company may differ significantly.

At the same time, it is possible to single out the main modules, without which it is difficult to imagine the operation of such systems. Here are some of them:

The technologies that are used to develop oil terminal management systems affect the performance of the software, the possibility of its development, the speed of implementation, and many other factors. Therefore, in order to select the optimal stack, our specialists perform some preliminary work:

It is also important what devices the software will be used on. There are different options here, for example, in the office it is convenient to use a desktop application, since it is characterized by maximum performance, and if the operator moves around the terminal, it would be more appropriate to use a mobile application that can be installed on a smartphone or tablet.

Based on this, the final technology stack might look like this:

The implementation of oil terminal management systems is often carried out according to the iterative SCRUM methodology.

The project goes through six main stages of development. Let’s consider them in more detail.

Stage 1. Gathering information

To create the most effective product, specialists need to fully immerse themselves in the client’s business, study its internal processes, as well as the vision and wishes regarding the implementation of new software. To find answers to these and other questions, our managers hold meetings with customer representatives.

Stage 2. Design and technical documentation

The design process lays down the logic and functionality of the future terminal management system, thanks to which the client will be able to understand exactly how the software will work even before its technical development begins. At the design stage, our specialists create:

After that, to present the prototype to the client, demonstration videos are created, in which all the features of the system being developed are described in voice and on real examples.

Stage 3. Design development

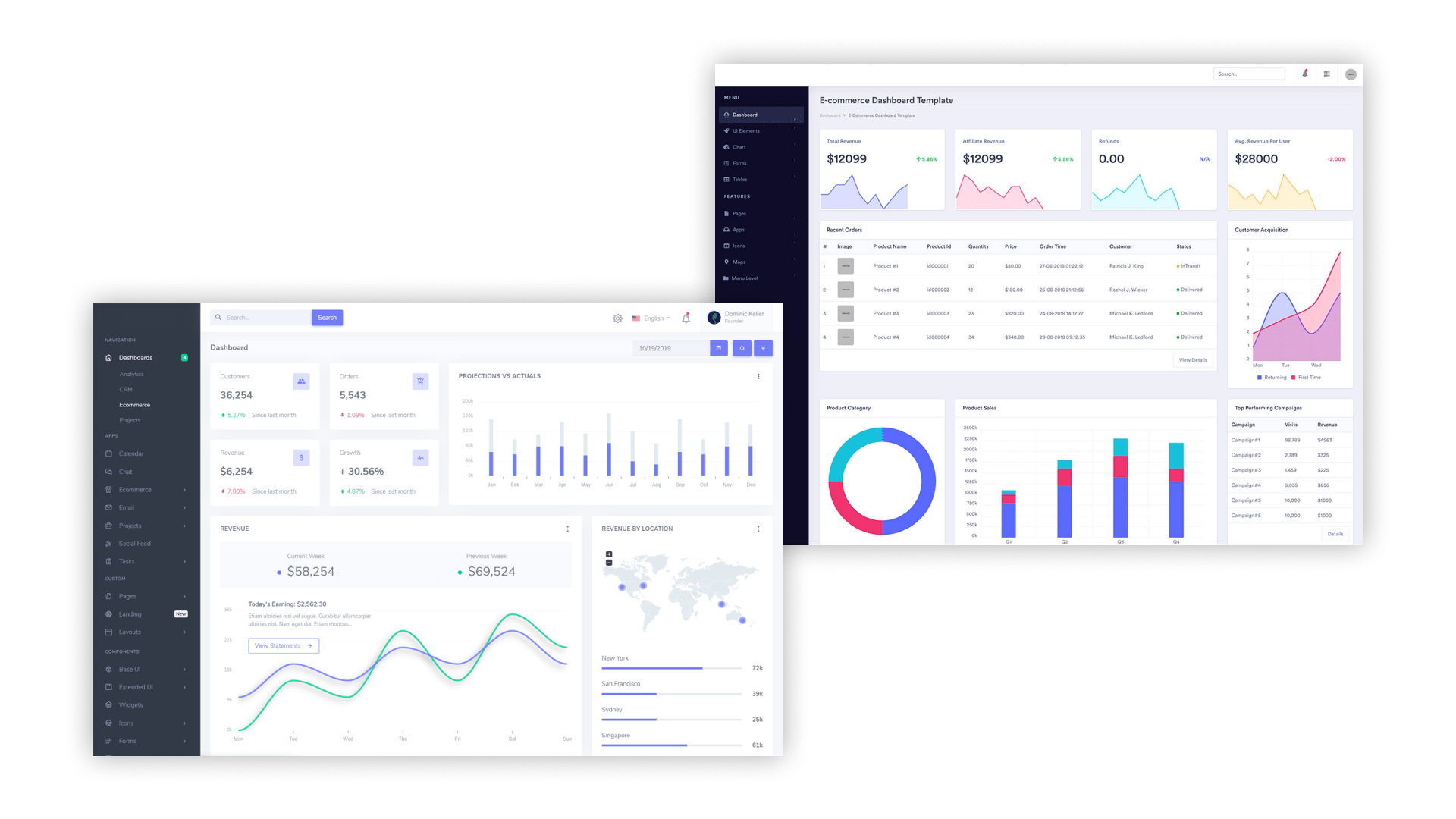

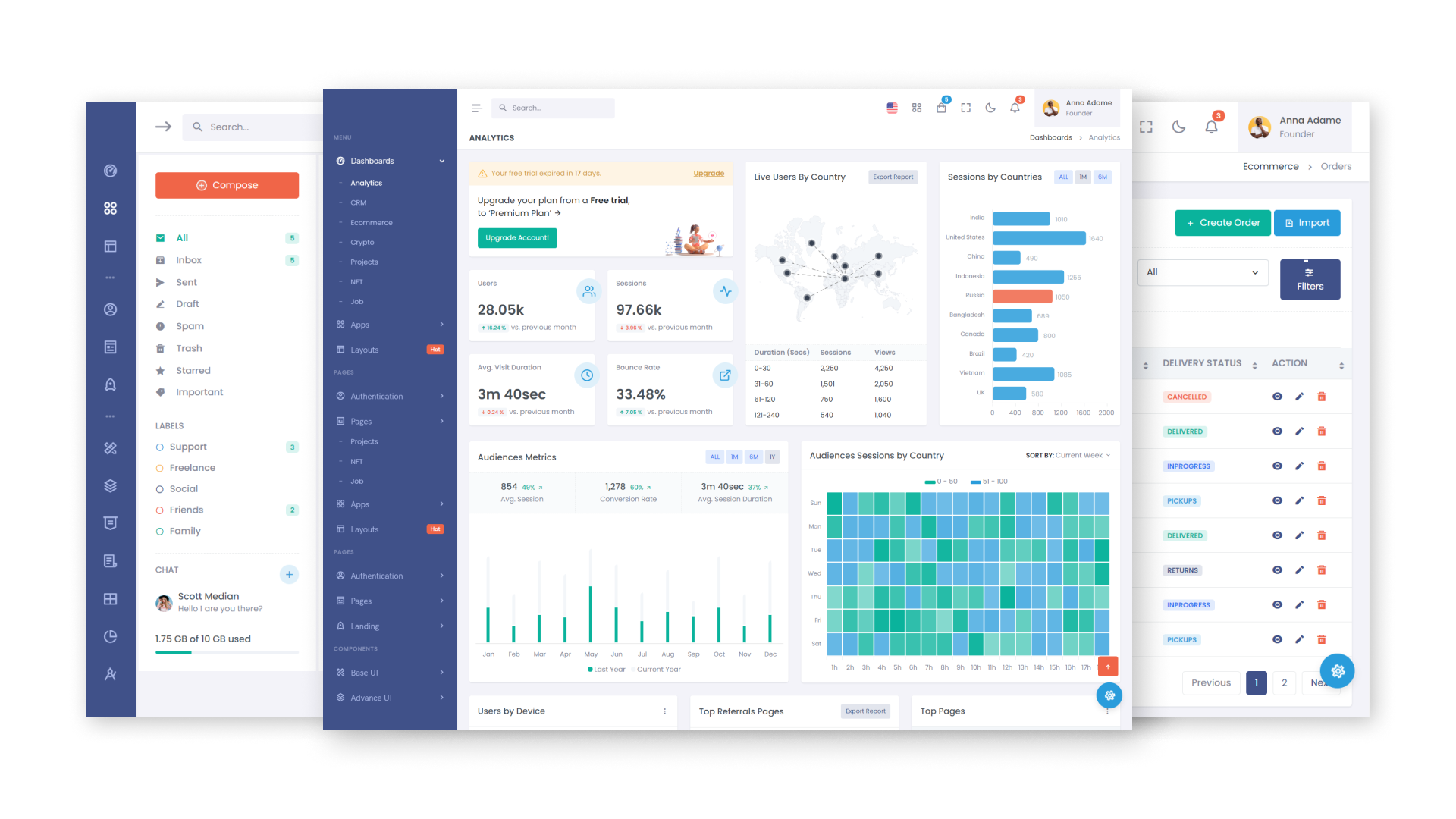

A convenient and thoughtful visual environment will greatly simplify user interaction with the control system. As a rule, for such projects, the design is developed individually, taking into account the functionality and in compliance with the principles of UI / UX.

Stage 4. Programming

At the technical development stage, programmers create the front-end and back-end of the software. Accordingly, this is the client part, with which users interact, and the server part, which is responsible for all internal processes, interaction with databases and functionality. Then they communicate with each other using the REST API, server application or other architectures and work as a single entity. Embedded development is also included in the programming phase, but is performed separately. It involves the creation of software that will interact with the electronic filling of various devices, control and manage the hardware. For example, it can be created for elevators, temperature and pressure sensors, scales and other devices that are used in the operation of the terminal.

Stage 5. Testing

After the development is completed, you need to make sure that all the created functionality works correctly and in the way it was intended during the design. To do this, QA engineers are connected to the project, who perform versatile testing of systems, find errors and control their elimination.

Stage 6. Technical support and development

For the first time after the deployment of the management system, your staff may still encounter various unforeseen problems. To eliminate them as quickly as possible, the project is transferred to maintenance. It is also worth adding that you can continue developing the system even after the release, and refine its functionality an unlimited number of times. Thanks to this, it will grow in parallel with the business and will not become obsolete over time.

Using the management system, you can automate many processes at the oil terminal, get rid of bureaucracy, increase the security of facilities and open up new opportunities for expanding your business. Our team AVADA MEDIA has extensive experience in developing such software.

Each of our solutions is aimed at optimizing complex tasks: from receiving oil products and monitoring reserves, to processing products and loading onto tankers. In this way, we help businesses work faster and more efficiently, and consequently, earn more money.

Our works

Contact the experts Have a question?

The user, filling out an application on the website https://avada-media.ua/ (hereinafter referred to as the Site), agrees to the terms of this Consent for the processing of personal data (hereinafter referred to as the Consent) in accordance with the Law of Ukraine “On the collection of personal data”. Acceptance of the offer of the Consent is the sending of an application from the Site or an order from the Operator by telephone of the Site.

The user gives his consent to the processing of his personal data with the following conditions:

1. This Consent is given to the processing of personal data both without and using automation tools.

2. Consent applies to the following information: name, phone, email.

3. Consent to the processing of personal data is given in order to provide the User with an answer to the application, further conclude and fulfill obligations under the contracts, provide customer support, inform about services that, in the opinion of the Operator, may be of interest to the User, conduct surveys and market research.

4. The User grants the Operator the right to carry out the following actions (operations) with personal data: collection, recording, systematization, accumulation, storage, clarification (updating, changing), use, depersonalization, blocking, deletion and destruction, transfer to third parties, with the consent of the subject of personal data and compliance with measures to protect personal data from unauthorized access.

5. Personal data is processed by the Operator until all necessary procedures are completed. Also, processing can be stopped at the request of the User by e-mail: info@avada-media.com.ua

6. The User confirms that by giving Consent, he acts freely, by his will and in his interest.

7. This Consent is valid indefinitely until the termination of the processing of personal data for the reasons specified in clause 5 of this document.

Send CV

Contact us in any convenient way for you:

+ 38 (097) 036 29 32